Dragline bucket optimization

This research was undertaken for VR Steel as a THRIP/TIPTOP project. The aim was to model the filling process of a dragline bucket using DEM and predicting the bucket motion, the filling rate and the drag forces. It included experiments using a scaled replica of a bucket used by industry at the time.

Dragline experiment and numerical models.

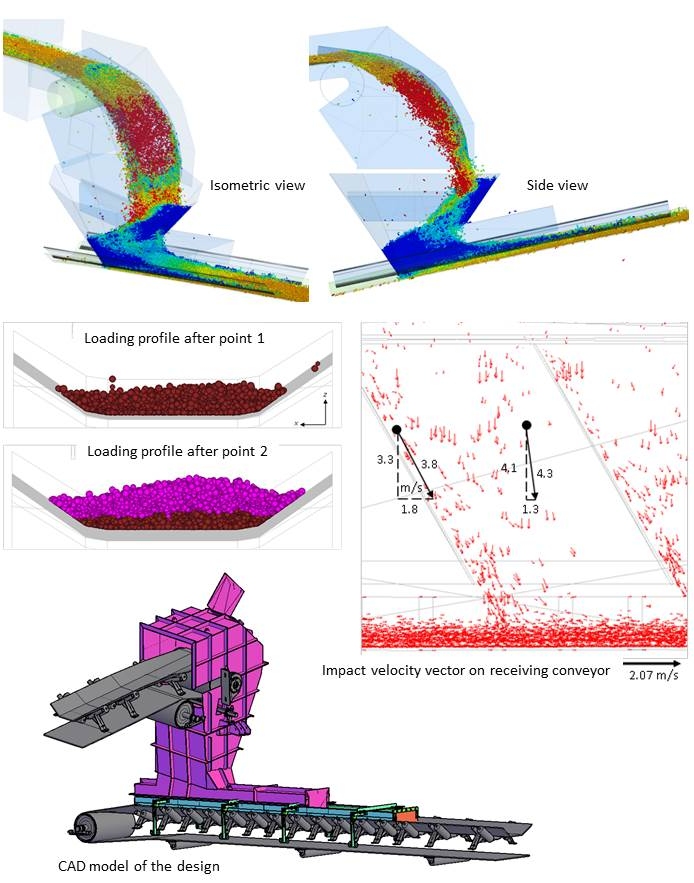

Conveyor transfer points

Two project were undertaken to model conveyor trans-fer points using DEM. In the first project, a Platinum ore transfer chute was analysed for Anglo American with the aim to critically evaluate the new design in terms of maximum possible material flow rate, impact angles and velocities, loading profile and spillage.

In the second project, twelve Kimberlite transfer chutes (with flow rates up to 530 t/h) were analysed for ADP Projects. The chutes were in the final stages of the design process and the DEM models were again used to evaluate the designs. The one conveyor belt had two loading points and was evaluated in terms of the criteria described above, and specifically at the second loading point where it was unknown how the material would load on an already loaded belt and if it would be able to handle the total flow rate.

Examples of conveyor transfer chute analyses.

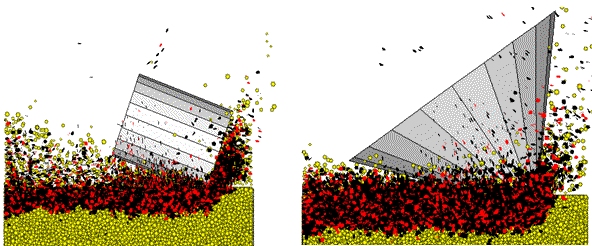

Rock drill and cutting

This project was undertaken together with Element Six to model the rock cutting process and the influence of tool wear.

DEM simulation of rock cutting using a button cutter (left) and pick cutter (right).