Vibrating subsoiler

This was an in-house research project to investigate the draft force reductions encountered by vibrating ploughs. The aim was to obtain a better understanding of the phenomena and to optimize the performance of such implements. The DEM parameters of the cohesive soil included contact bonds and all parameter values were carefully calibrated. The models were used to investigate the mechanisms involved in breaking the soil under vibration.

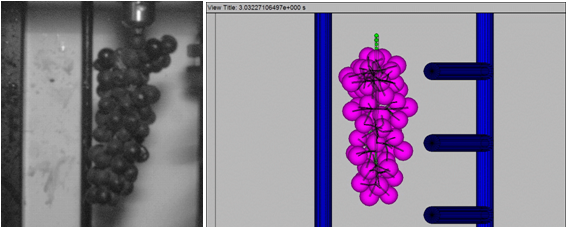

Vibrating subsoiler field test (left) and DEM model (right)

Centrifugal fertiliser spreader

There is a need in the fruit industry for fertiliser spreaders that can deliver the fertiliser in a specific pattern to minimize wastage. This in-house project was undertaken to investigate the performance and optimize the design of centrifugal fertiliser spreaders specifically for fruit orchards. DEM simulations could be used to test and evaluate new designs of which the most promising was tested experimentally.

Centrifugal fertiliser spreader experiment (left) and equivalent DEM model (right)

Mechanical handling of soft fruit

This project was undertaken to model the handling of grapes with the focus on the de-stemming process (the removal of the berries from the stems). It included laboratory and field experiments and calibrated DEM models of a commercial de-stemming machine. The percentage of berries successfully removed from the stems could be predicted and also the number of impurities (such as stems) that would end up with the berries.

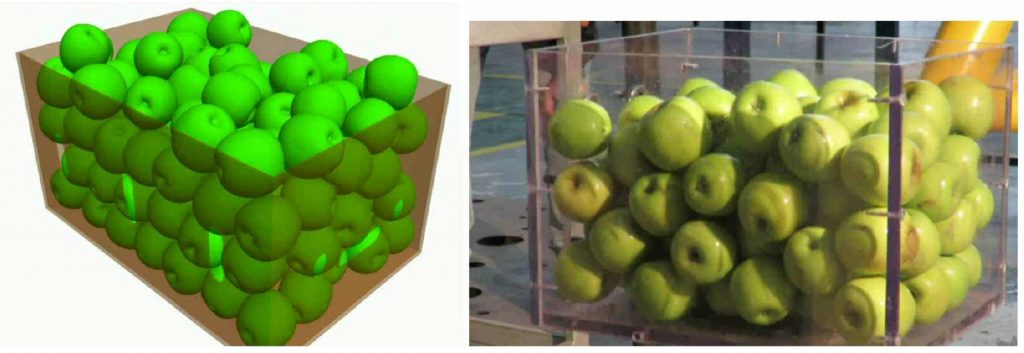

In a more recent project, DEM is used to predict the bruising of apples during handling and transport. This include the development and implementation of appropriate contact models, the accurate modelling of the apple shape, and measuring of the contact properties using a pendulum device. The model is validated by predicting the total bruise volume of a vibrating box filled with apples.

De-stemming of grapes

Apples modelled as multi-sphere particles in a vibrating box