This case study is a quick but powerful demo of what X-ray CT inspection can do. The Samsung S7 used in the test is my own phone, 2 years old and not in use. This phone was released about the same time as the Samsung Galaxy Note 7 – which had battery explosions often. The S7 was also known to overheat (my own experience also), so let’s see what’s going on inside this phone.

edf

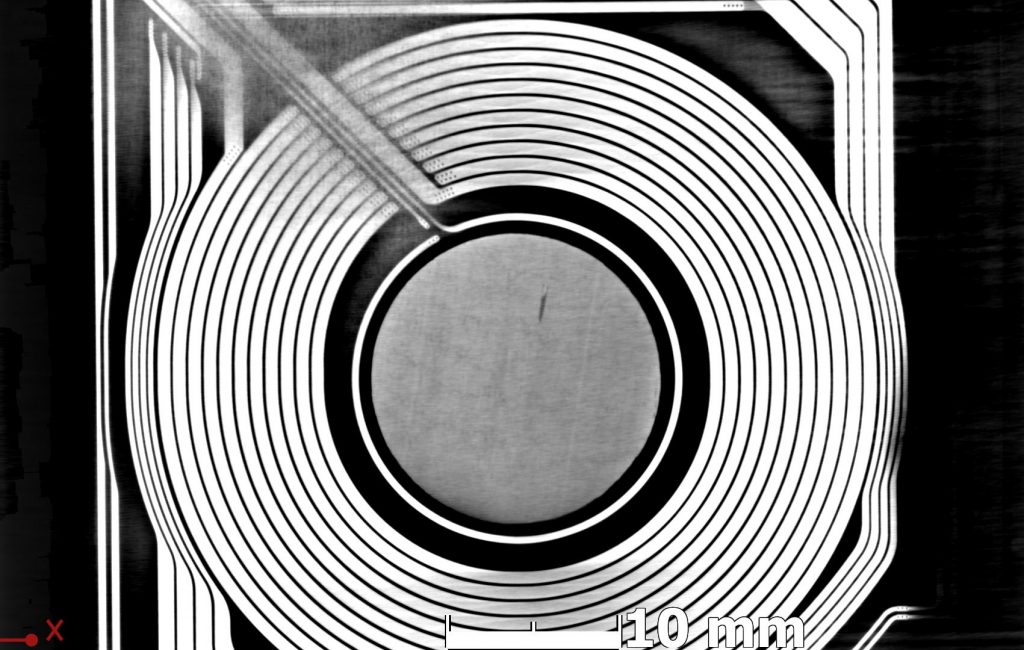

The top-view cross section of the battery shows its layers tightly wound up – the edges seem to be “compressed” into the tight-fitting space (top right for example). Seems like too much material for too small space, but no short circuits or flaws directly seen here.

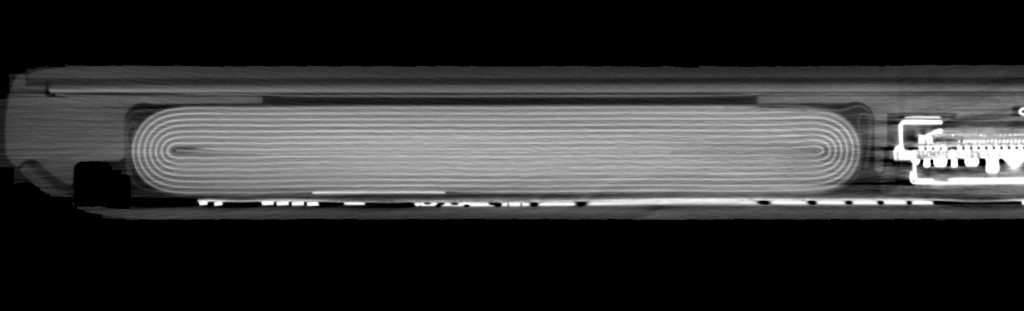

The only flaw found in this phone was a small indentation on the battery, behind the antenna (black stripe):

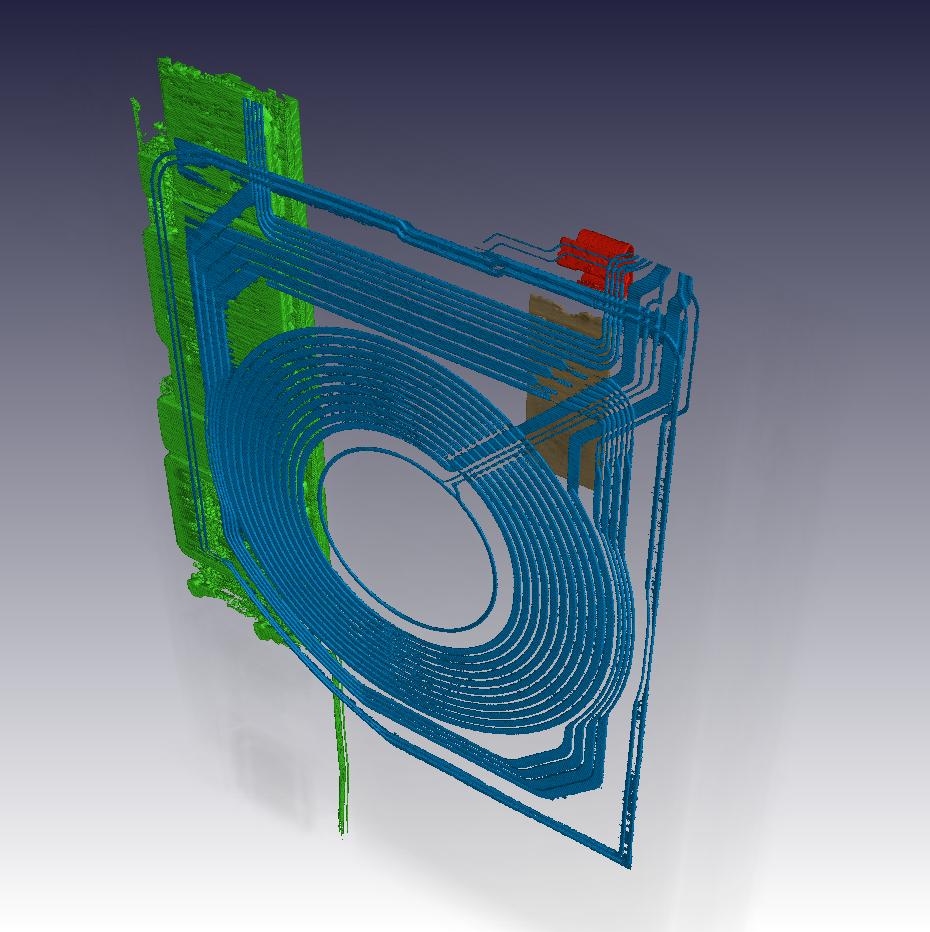

3D visuals helps to understand connectivity and orientation of different parts, for example this image shows some sections highlighted:

The following video shows the entire phone in 3D views of various internal sections, including inspection of electronics soldering pads – these always have some voids (air spaces) but they should not be too big, this one passes:

If you want to make a non-destructive test of your product, or want to apply this test to your research topic – contact us. This case study used an quick overview scan and a detailed high-resolution scan overlapped. Analysis by VGSTUDIO MAX 3.2.

Follow

Follow