This example shows a typical microCT analysis of 3D printed parts. 3D printing and additive manufacturing technologies differ widely and quality control of these parts are very important. In this example, Markforged parts were scanned of the following types:

1. Nylon

2. Short fibres in onyx plastic

3. Long fibres in nylon

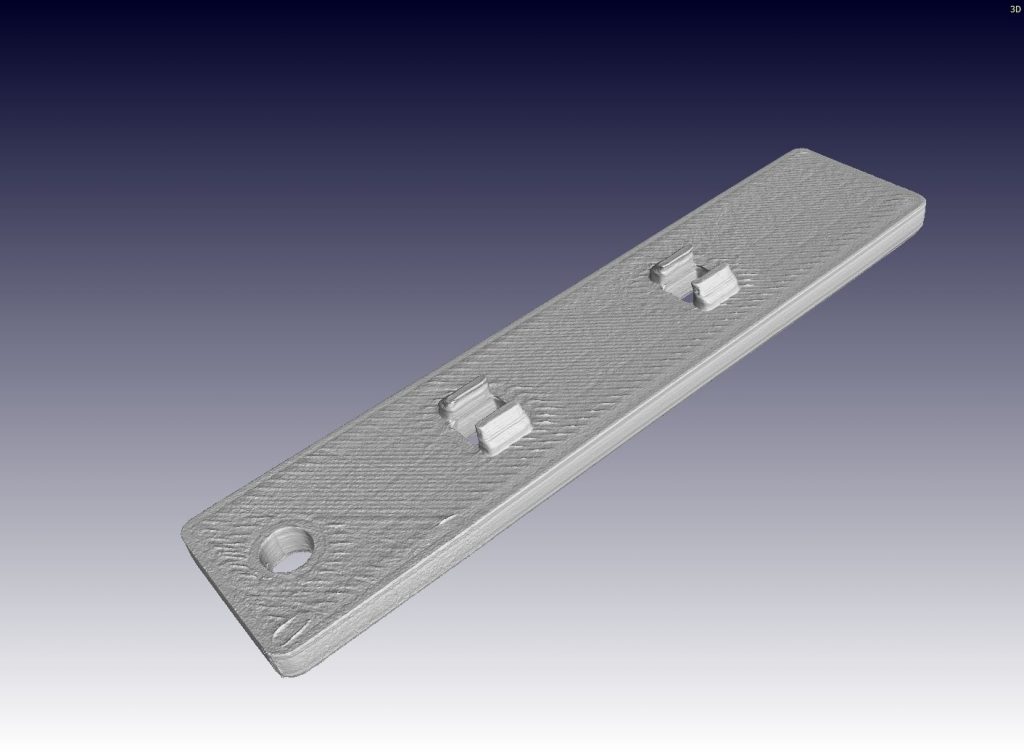

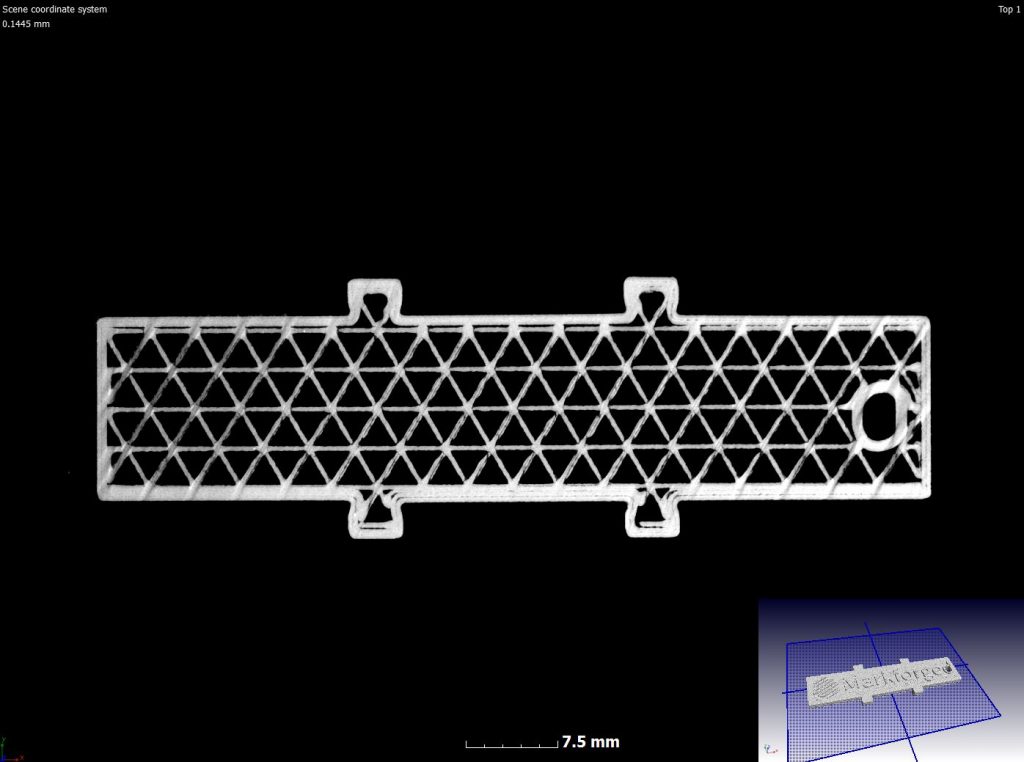

Here is a typical surface view of the nylon part, from which a STL file can be produced of the actual part.

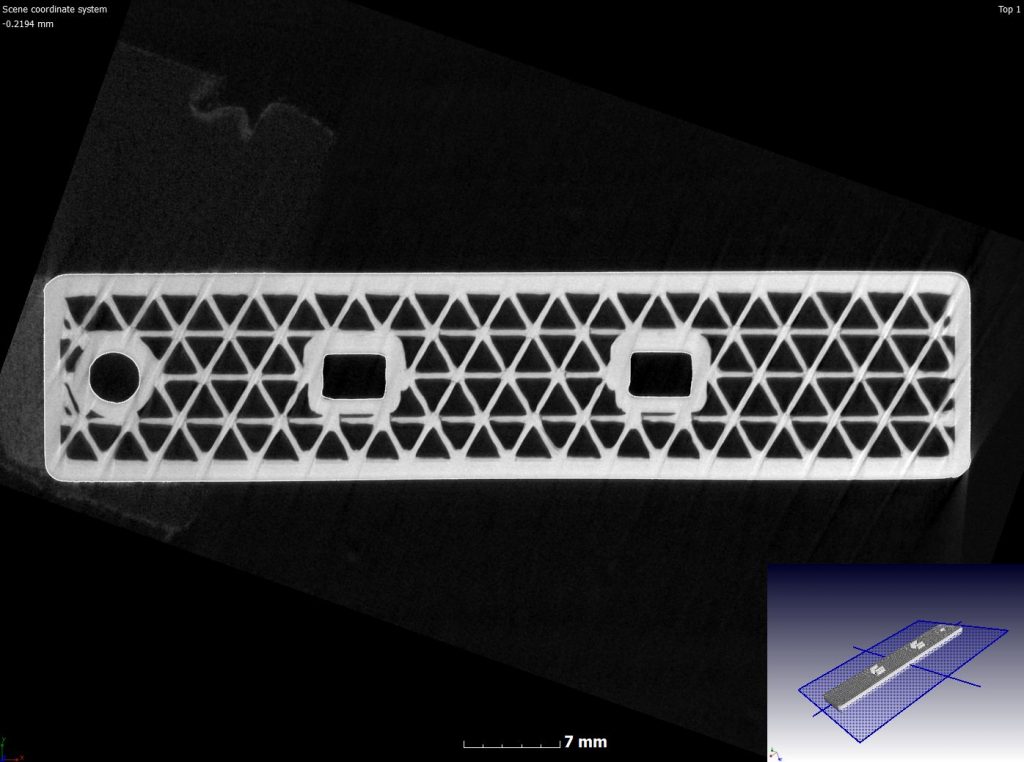

This is the cross-sectional view of the part, viewing the interior cavities and which can be used to assess possible build imperfections:

This is a closeup of the same scan data:

A typical microCT scan comprises of slice images across the part, this slice video gives a good idea of the method of assessing a part from slice images:

slice video

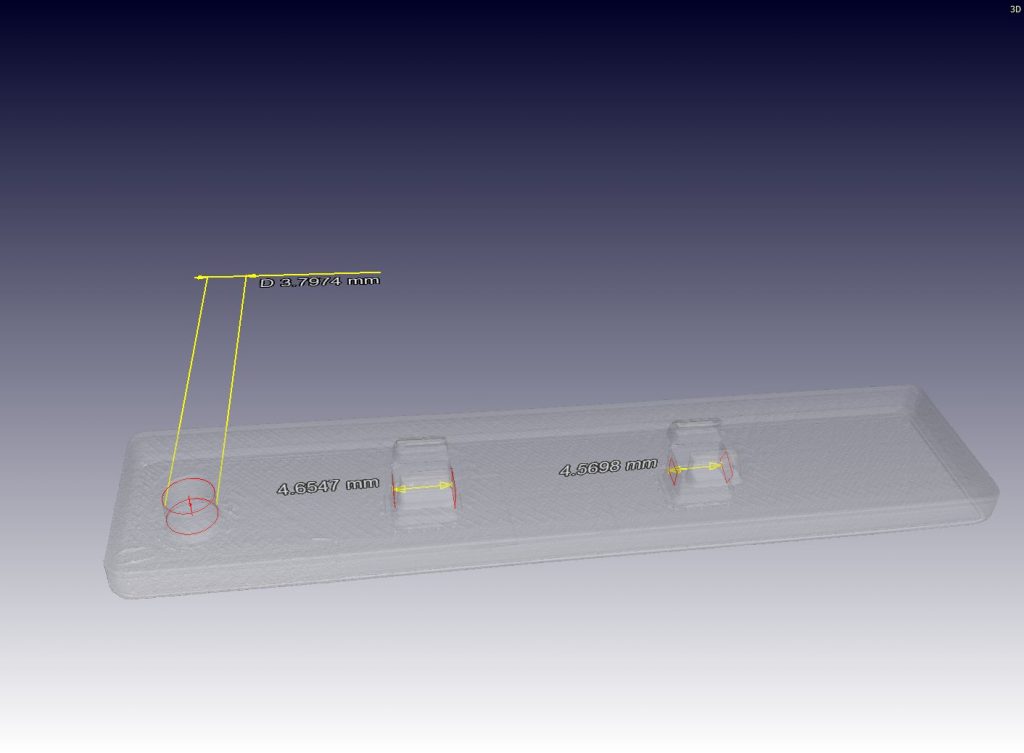

MicroCT allows dimensional measurements, such as measurement of critical hole diameters or distances. It is effectively a coordinate measurement device, when using appropriate scan quality and appropriate software (we use VGStudioMax 3.0 with the coordinate measurement module). This is an example of some measurements on this part:

And a video demonstrating the same: nylon Cordinate measurement

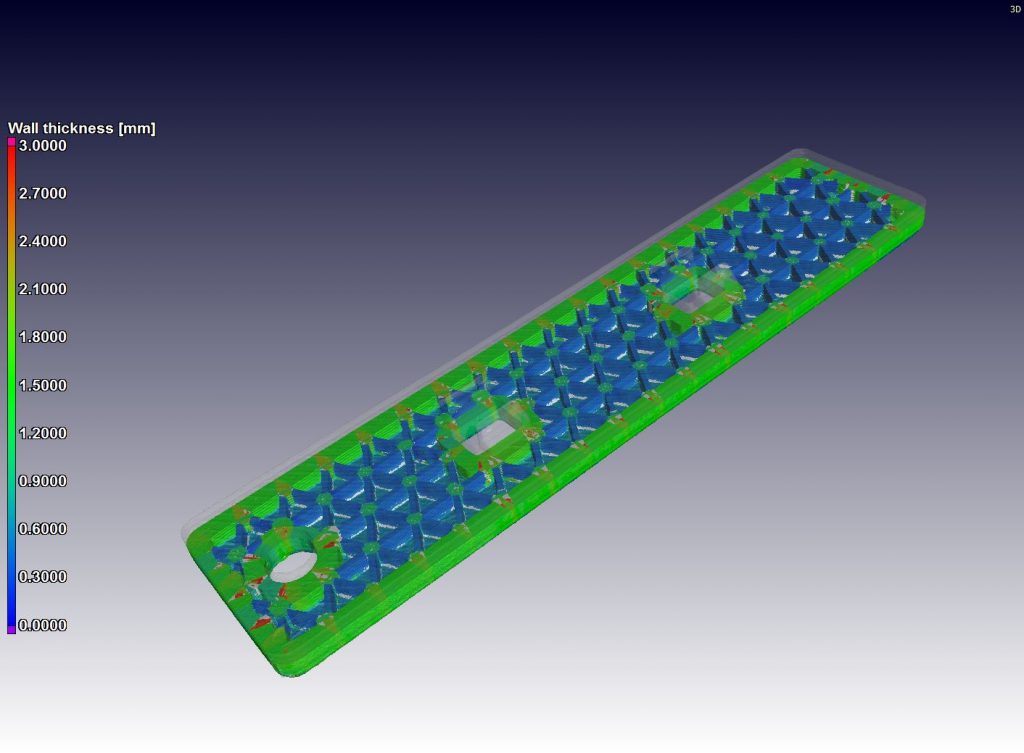

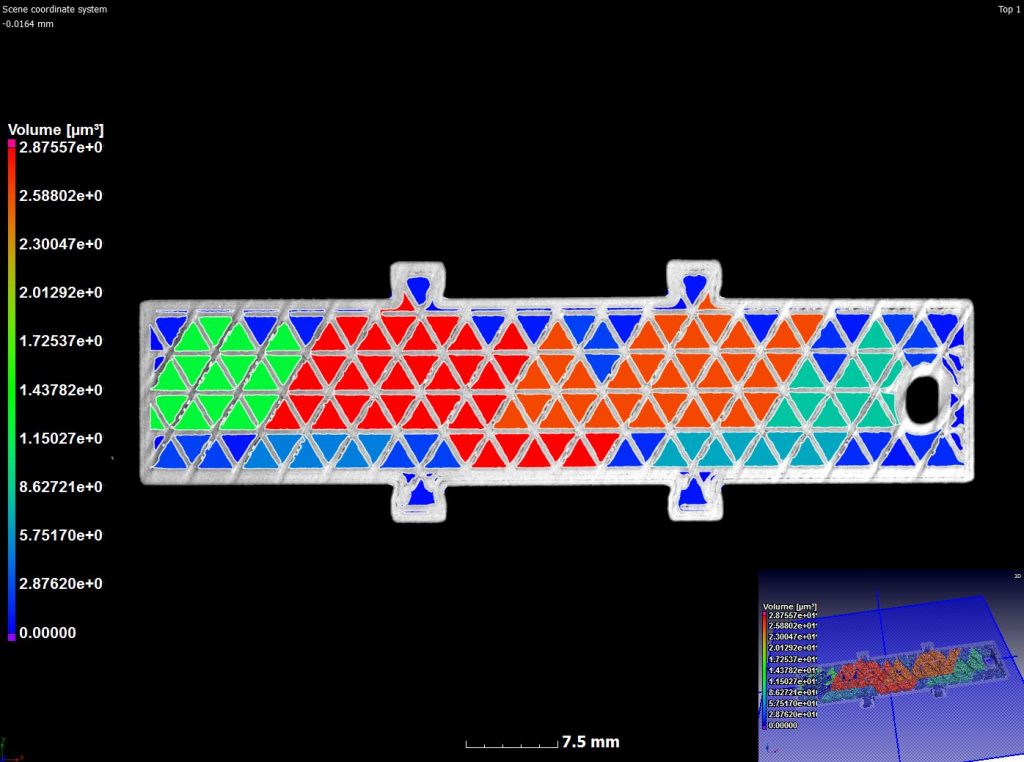

In addition, other routine measurement types are possible, in this case the wall thickness analysis allows measurement of the walls inside the part, see the image below:

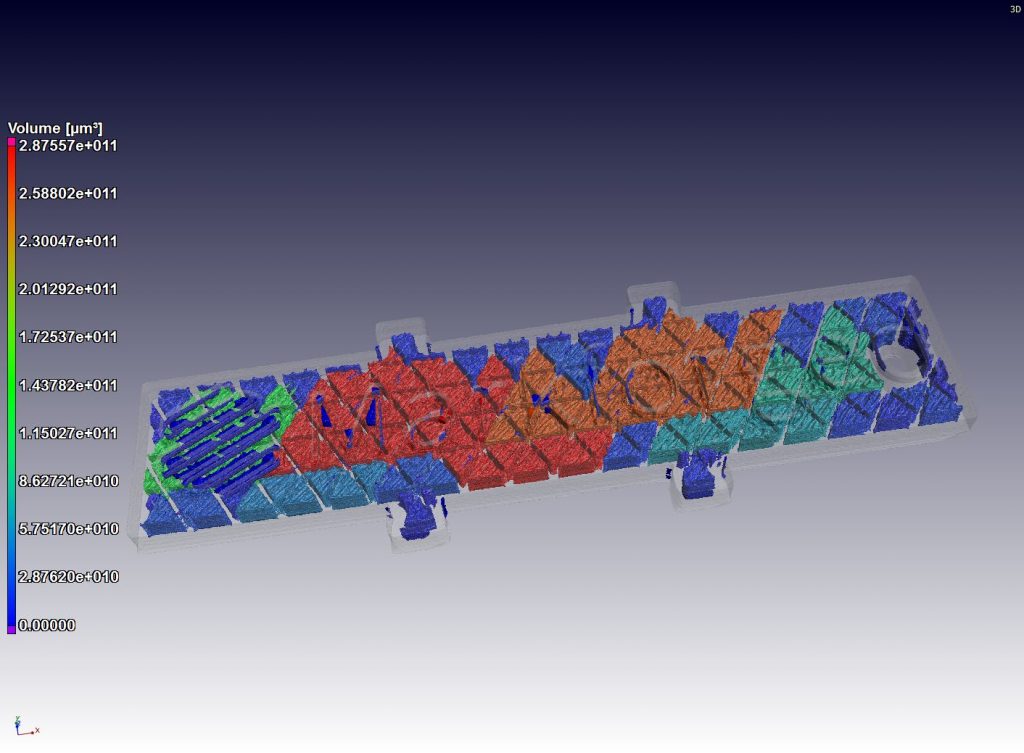

Defect or porosity analysis is usually applied to find small unwanted pores, in this case the large cavities could be highlighted using this method:

nylon defect analysis

The second part, which contains short fibres to increase its strength properties is shown here:

The cavities could be visualized in this part as well:

And some nice images, showing how microCT can not only be used for analysis but also for marketing:

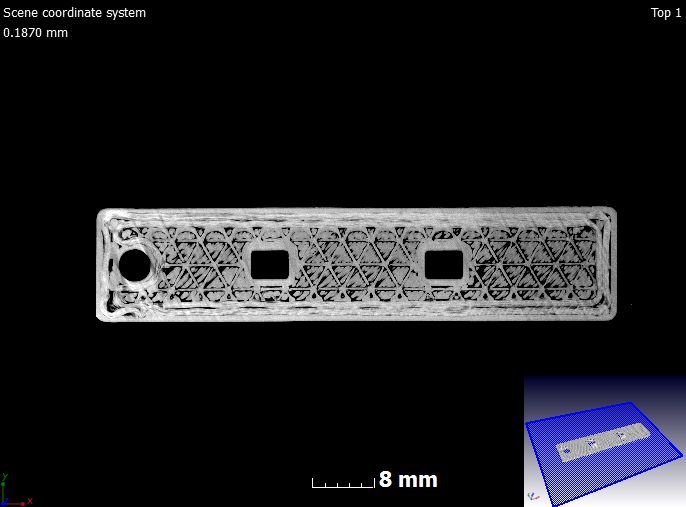

The third part is very similar but contains longer fibres for higher strength. The slice image is shown below:

Here is a video combining the three scans, and virtually putting the I-beam together: Combined

For more information on microCT analysis of 3D printed and additive manufactured parts, please see some articles below:

http://online.liebertpub.com/doi/abs/10.1089/3dp.2016.0012

http://online.liebertpub.com/doi/abs/10.1089/3dp.2015.0034

http://online.liebertpub.com/doi/abs/10.1089/3dp.2015.0015

Follow

Follow