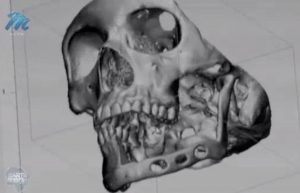

One of our clients from 2012/2013 contacted us with a private testing request: he fell with his mountain bike hitting his head very hard on a rock, causing serious whiplash. He wanted us to inspect possible damage to his helmet in the impact location. We performed two scans for this, one full-helmet scan and one …

Category: Industrial inspection

Feb 07

What is inside a Samsung S7 smartphone?

This case study is a quick but powerful demo of what X-ray CT inspection can do. The Samsung S7 used in the test is my own phone, 2 years old and not in use. This phone was released about the same time as the Samsung Galaxy Note 7 – which had battery explosions often. The …

Aug 02

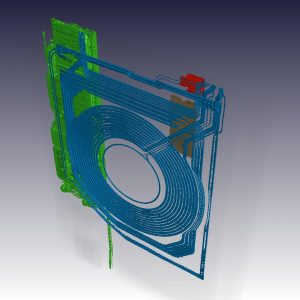

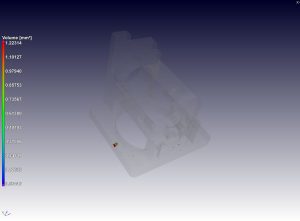

Analysis of 3D printed parts

This example shows a typical microCT analysis of 3D printed parts. 3D printing and additive manufacturing technologies differ widely and quality control of these parts are very important. In this example, Markforged parts were scanned of the following types: 1. Nylon 2. Short fibres in onyx plastic 3. Long fibres in nylon Here is a …

Follow

Follow