This video shows the 3D morphology of a crack in steel. This is used for failure analysis in various industries and for all kinds of products and materials. Such information (as crack morphology in 3D) is useful for safety investigations, lifetime prediction, failure root cause analysis for future prevention, and also for legal disputes. Video …

Category: Metals

Apr 10

CT scanning of cast metal parts

This is one of the best-known applications of X-ray inspection and CT scanning – to check cast metal parts for porosity and extent of porosity. Here one example with nice video showing the data and results available for such parts. CLICK HERE FOR A VIDEO OF CT RESULTS: casting1_small

Mar 18

X-ray CT inspection for medical implants

Introduction This case study was performed to demonstrate how routine X-ray CT inspection adds value to medical implant production, ensuring quality and reliability. This particular case is for 3D printed (additively manufactured) titanium hip and knee implants but the methodology is applicable to all manufacturing techniques, not only additively manufactured implants. X-ray CT inspection is …

Jan 17

Bike frame scanning

Nov 01

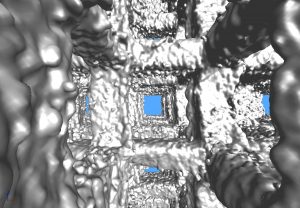

View from the inside

This is a microCT image of the inside of a 3D printed metal lattice structure – the struts are 0.75 mm wide and rough as built by laser melting of metal powder.

Aug 03

Metal casting analysis

Metal castings typically contain porosity which can affect the strength and lifetime of the part. Excessive porosity can be reduced by optimizing the casting parameters, and the best way to do this is to visualize and quantify defect sizes by X-ray microCT. It is also possible to routinely check castings to ensure nothing changes in …

Aug 02

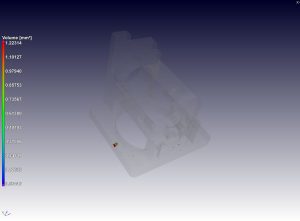

Medical implant testing

X-ray microCT is nondestructive and therefore is used for testing produced parts for porosity or inclusions (defects) and sometimes for wall thickness or deviation from CAD design. All these types of analysis can be used to assess a part before implanting it into a patient. We provided this service for a recent implant patient who …

Apr 24

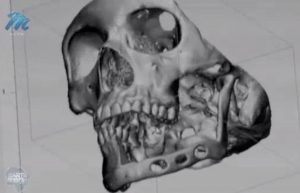

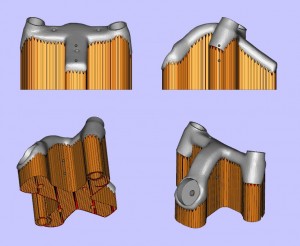

Medical implant: metrology day example

- By Prof Anton du Plessis in Metals

Custom medical implants can be made to suit an individual patient using additive manufacturing (3D printing) technology. Below is the design file of the custom titanium implant including support structures. The part was designed and built at the Centre for Rapid Prototyping and Manufacturing (CRPM) at the Central University of Technology (CUT) in Bloemfontein, South …

Mar 17

Non-destructive testing Case Study

- By Prof Anton du Plessis in Metals

This post shows the type of analysis possible for commercial non-destructive testing customers, specifically to demonstrate what is possible and at what cost. Costs are excluding 7% admin fee and excluding VAT at 14%. It is laid out in a step by step process, where a typical customer will make use of steps 1-3 while …

Feb 09

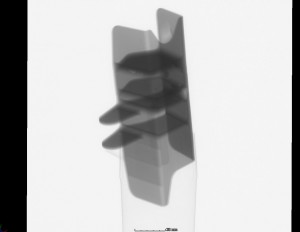

Image Quality Indicator

- By Prof Anton du Plessis in Metals

Image Quality Indicators (IQIs) are used in commercial 2D X-ray inspections to confirm detail detectability of the system. In the simplest case these are wires with well known thicknesses. It is not generally well known that 3D X-ray systems can also make 2D inspections very easily and shown below are such images of a standard …

CT Scanner facility

3D X-ray, X-ray microscopy, Industrial CT, Non-Destructive Testing Services

Follow

Follow