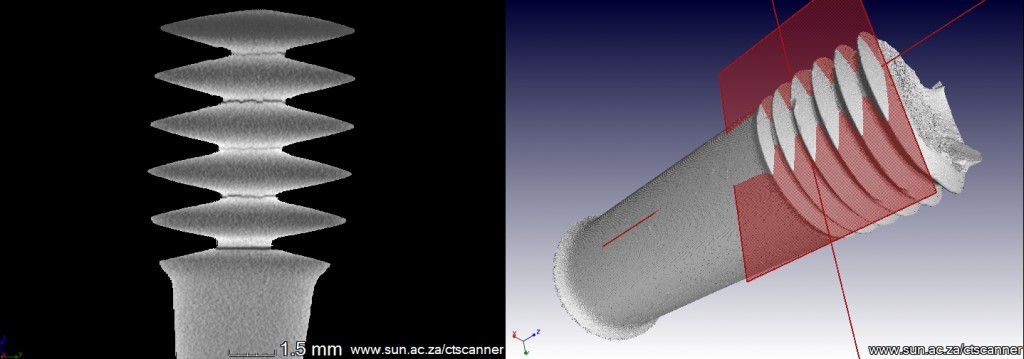

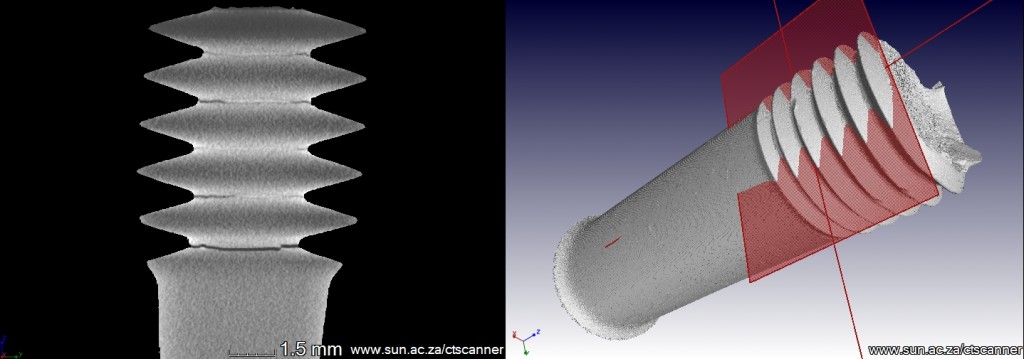

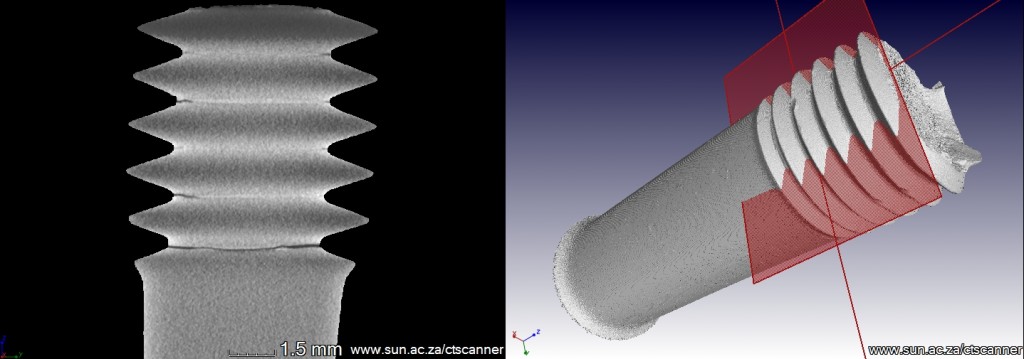

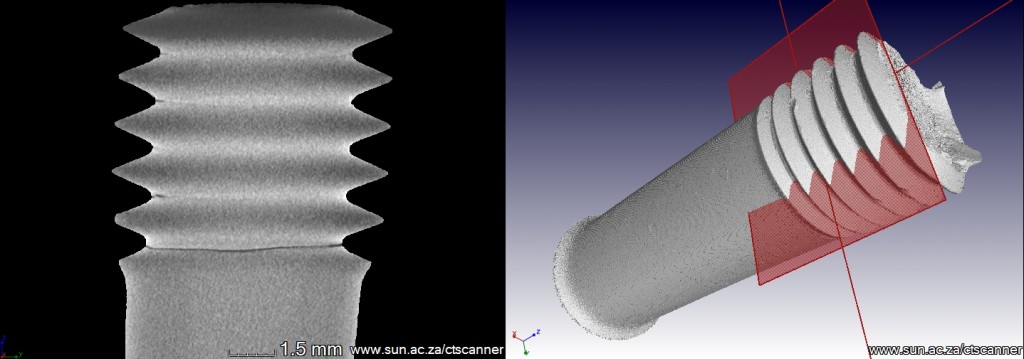

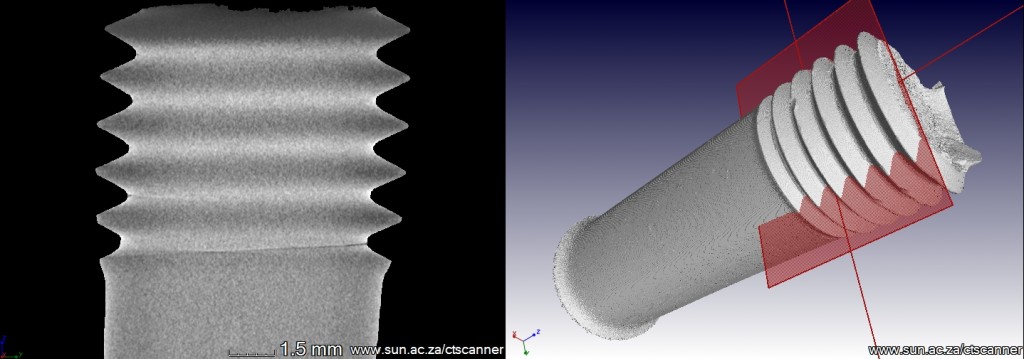

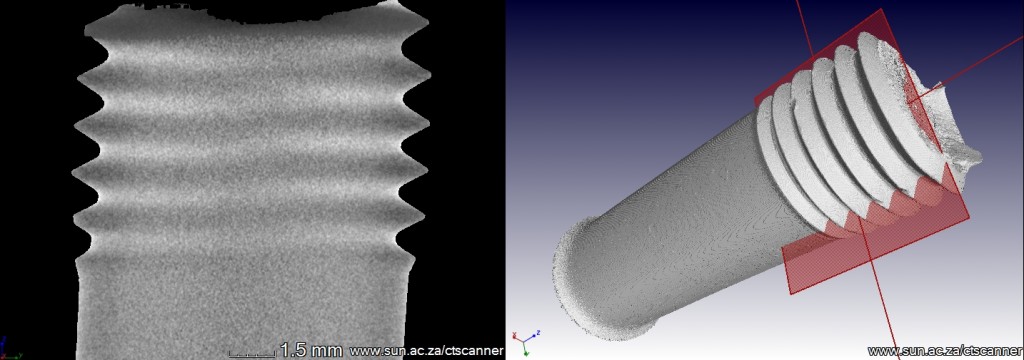

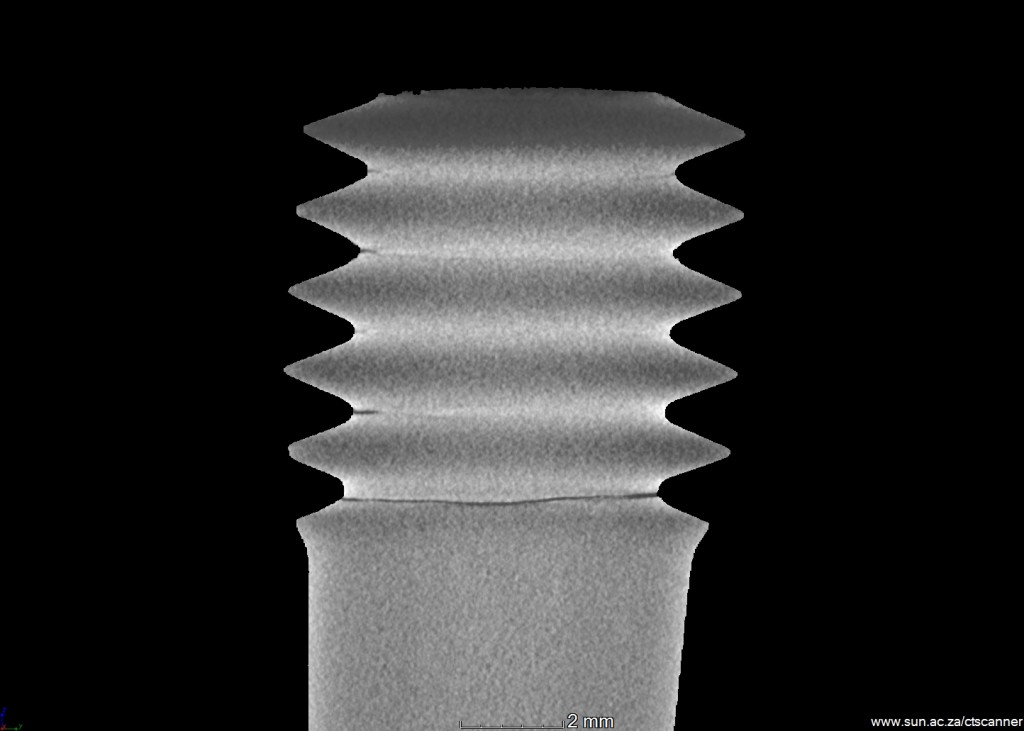

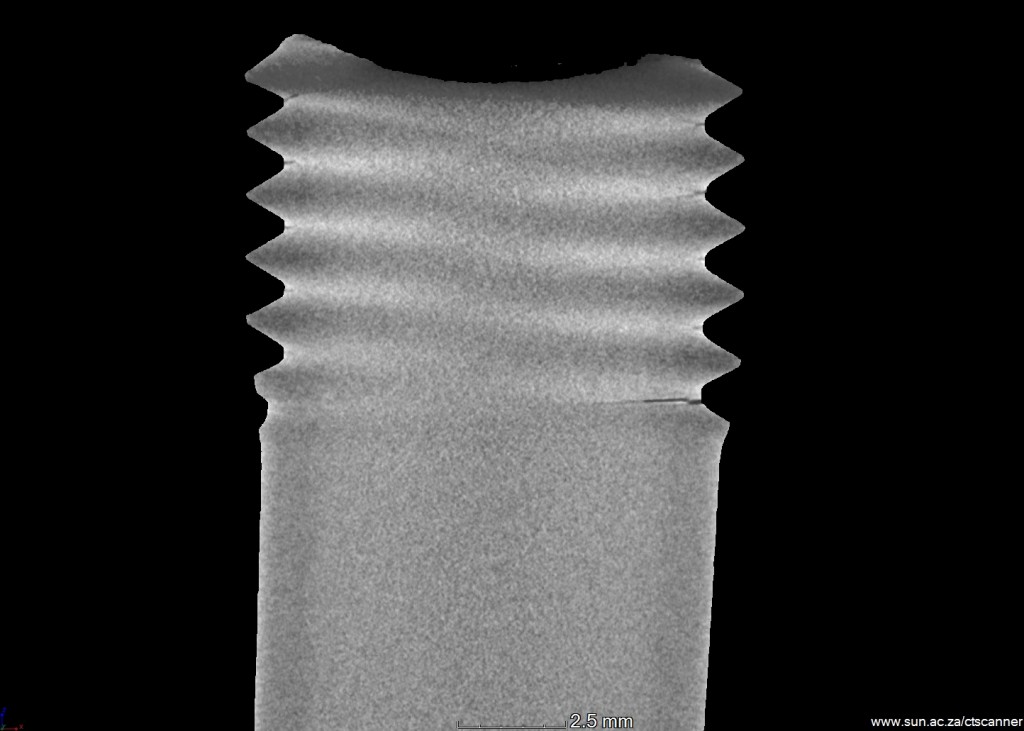

Two of the four bolts holding the engine of a 5 year old car of a well known German brand broke off, apparently after driving over a Johannesburg speedbump. The customer sent the broken bolt for a microCT scan for further inspection, with images showing the results below (cracks are black lines). Clearly, there are cracks mostly to one side of the bolt, indicating bending stress as a potential cause of failure. Bending stress would have caused one of these cracks to propagate until breaking clean off, leaving the engine hanging on the remaining 2 of 4 bolts.

The example shows clearly how cracks can be visualized within metal components. It also shows cars need to be manufactured to more stringent requirements for South African conditions, and that much more nondestructive testing needs to be done, ideally at our facility.

Follow

Follow