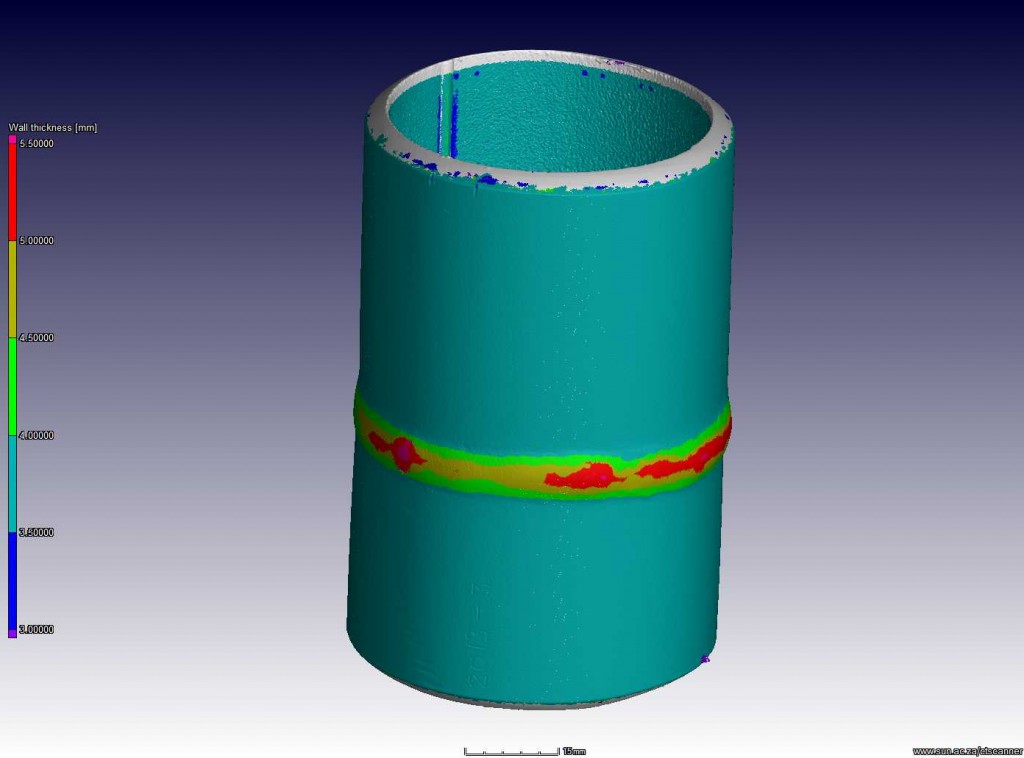

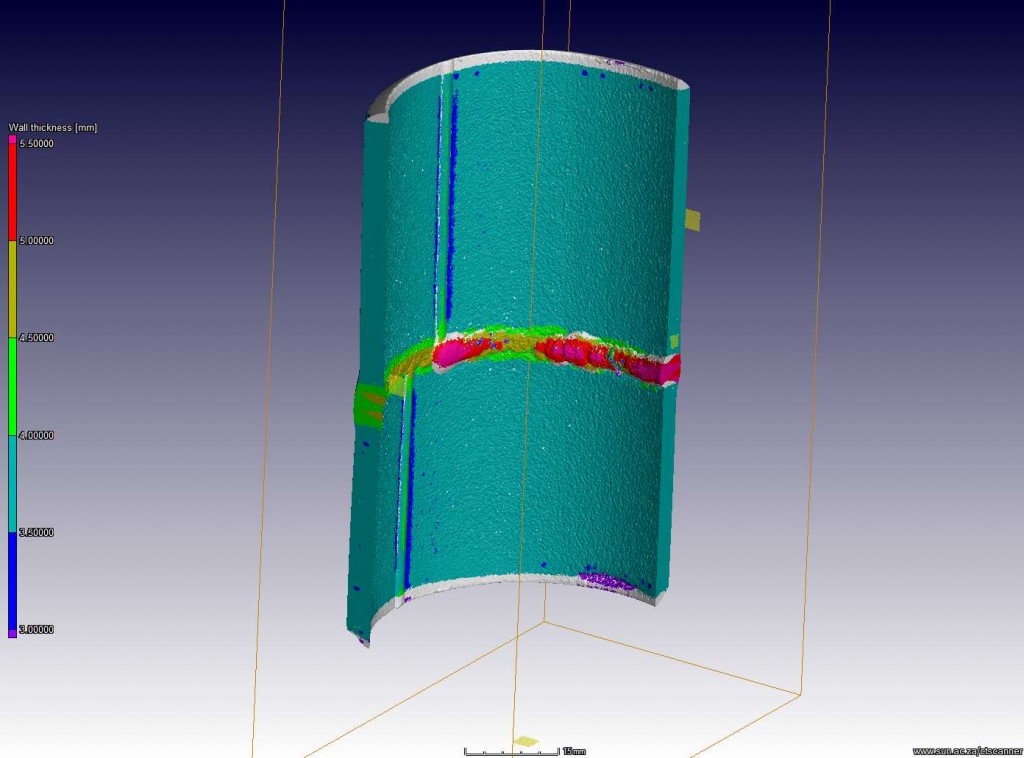

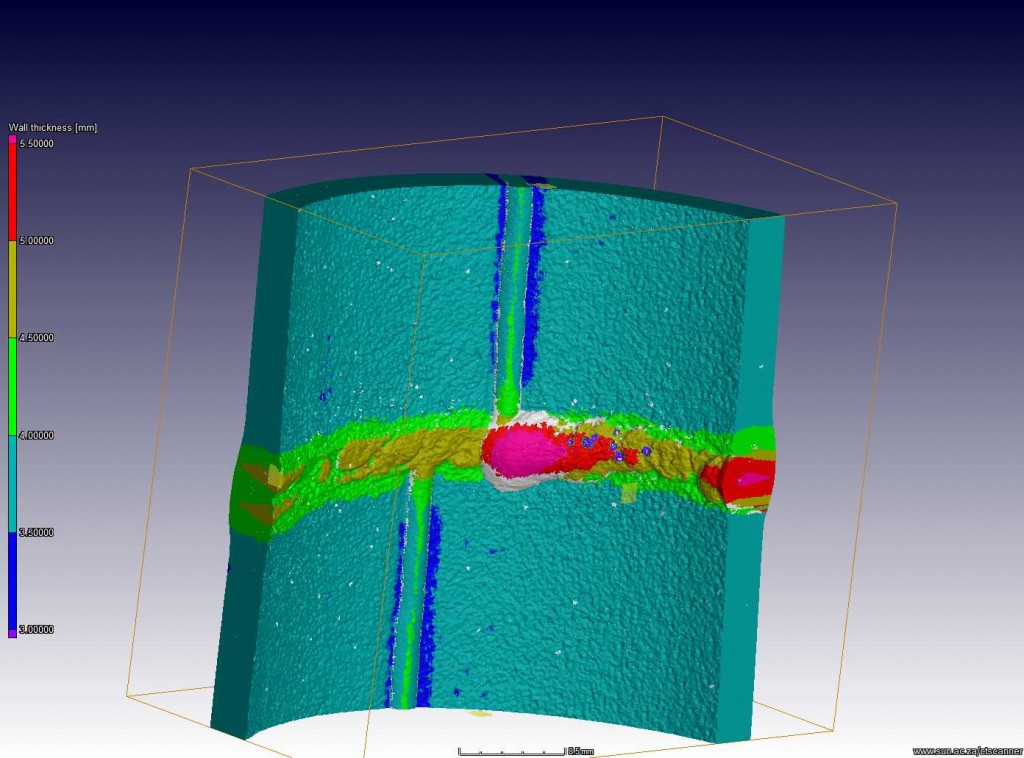

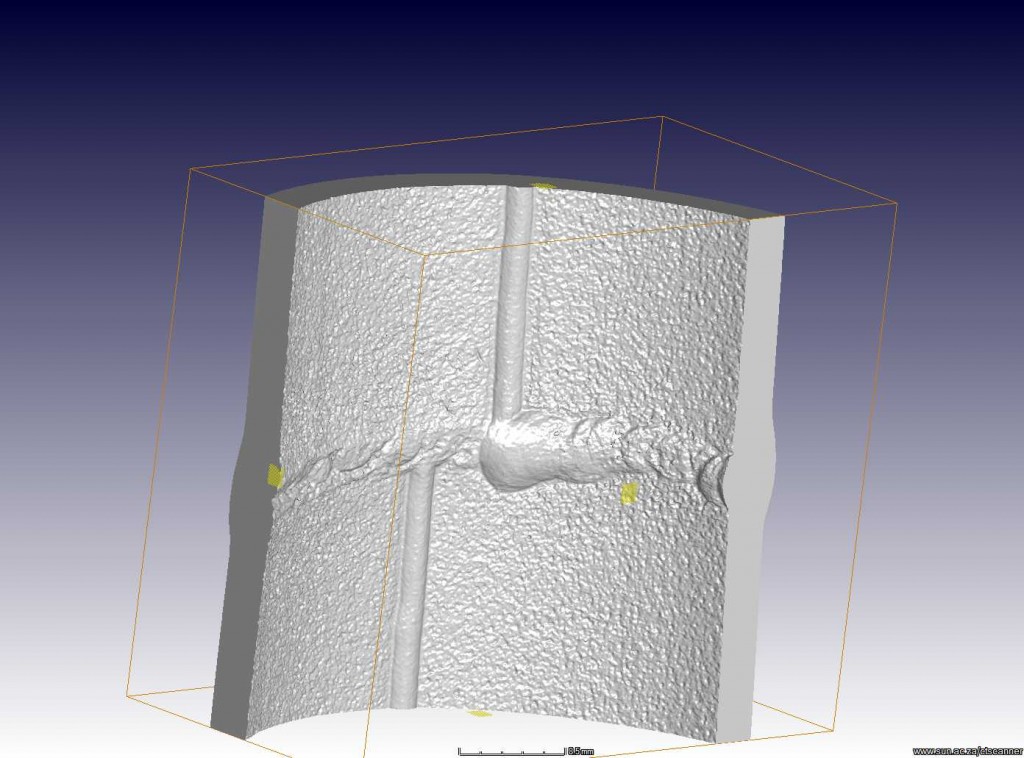

X-ray testing of metal parts is used widely to find flaws, defects, cracks, pores or even inclusions which all can have serious effects on the part’s mechanical properties. CT scanning provides an “X-rays on steroids” advantage. Much more detail is visible and full 3D data can be analyzed to create a colour coded thickness analysis to visualize the variation across a weld. In this sample, the steel cylinder has a weld zone with a reasonably good thickness variation as shown in the colours varying from 4-5.5 mm and the entire colour bar is from 3 to 5.5 mm to enhance the variation viewing. No internal pores were found in this example, but some inclusions (denser material) were found on the inner surface of the weld at the thickest part (not shown here).

Thanks to the guys at NASA (that’s in Bellville not Houston) for loaning the test sample.

Follow

Follow