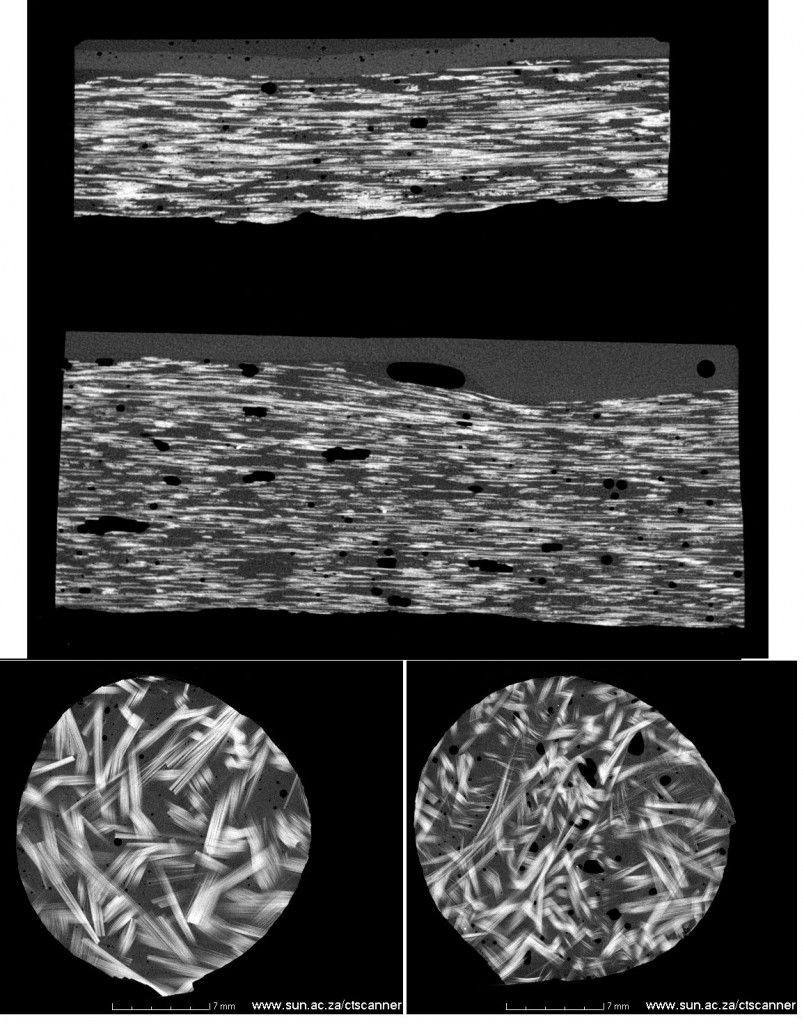

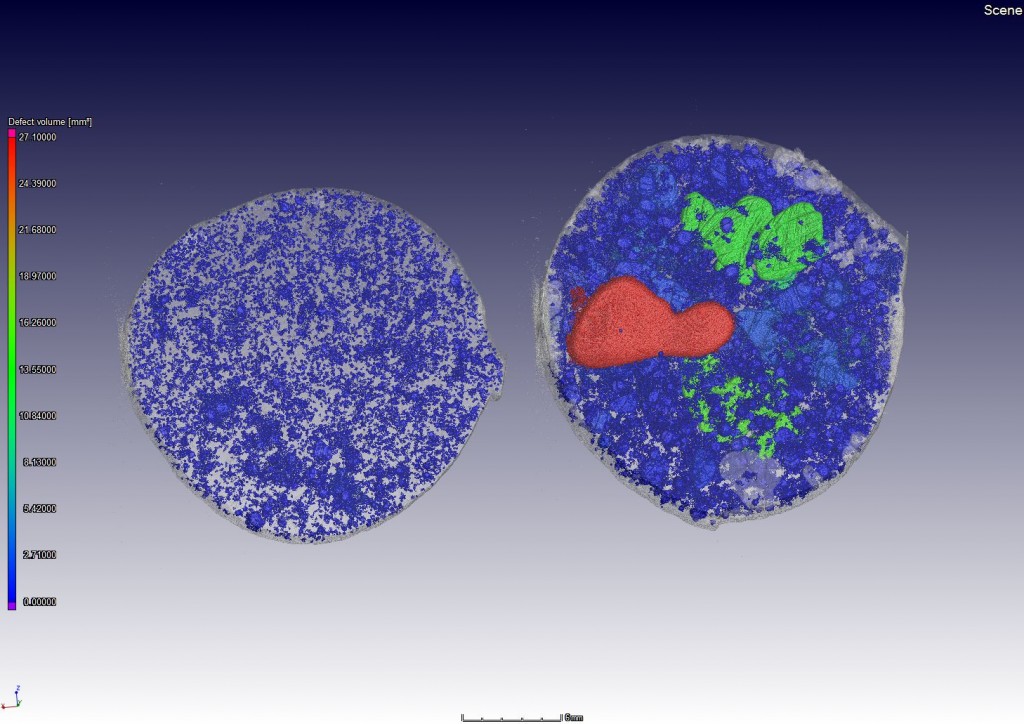

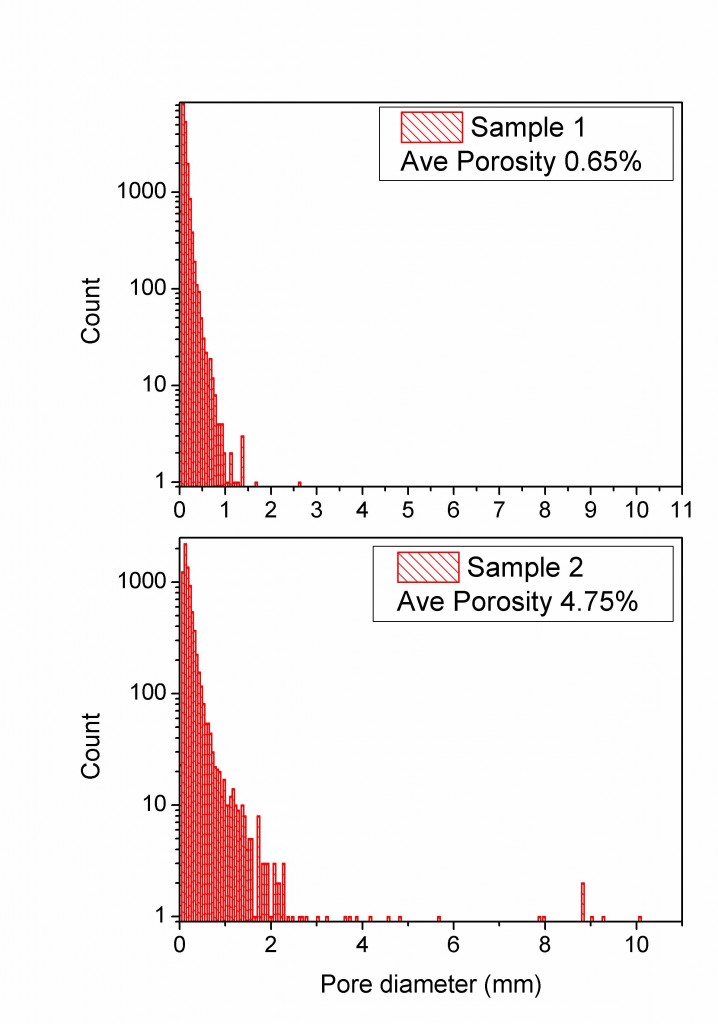

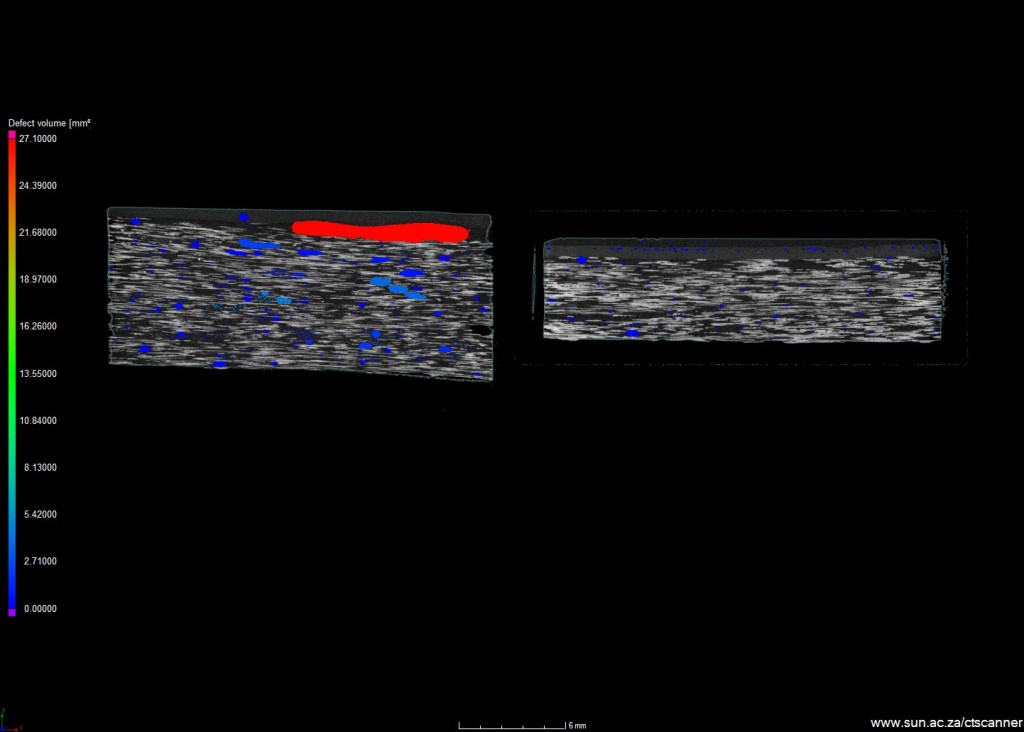

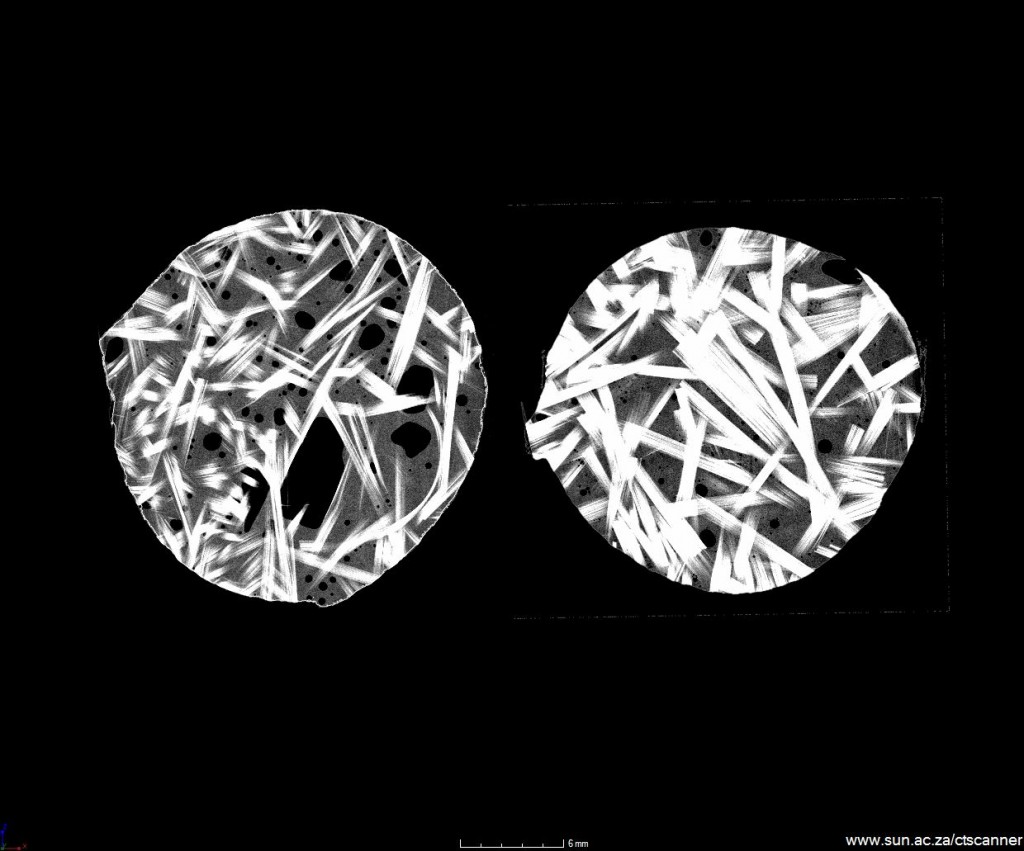

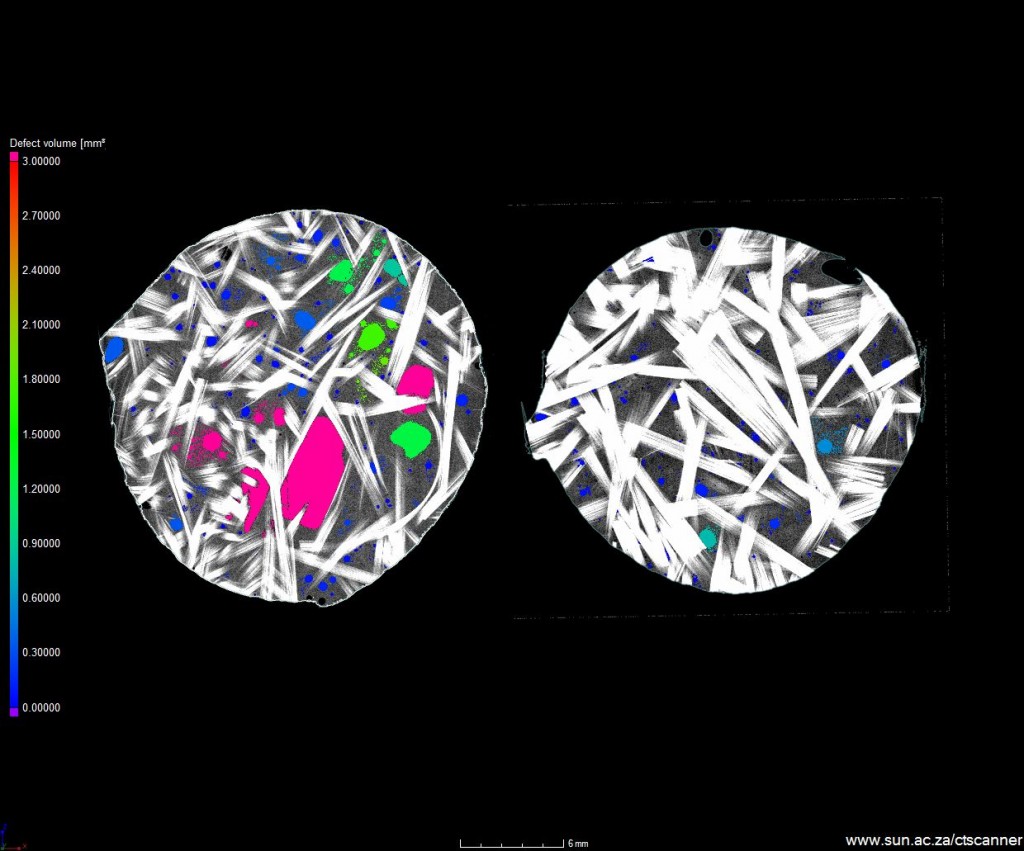

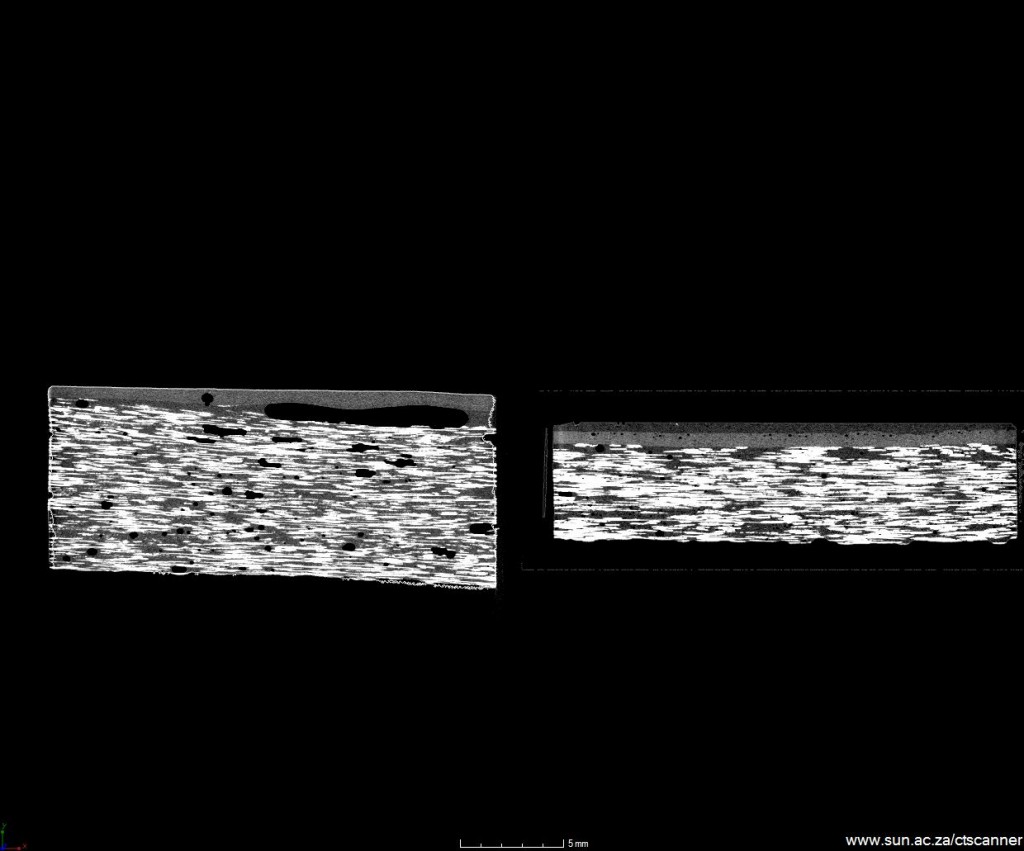

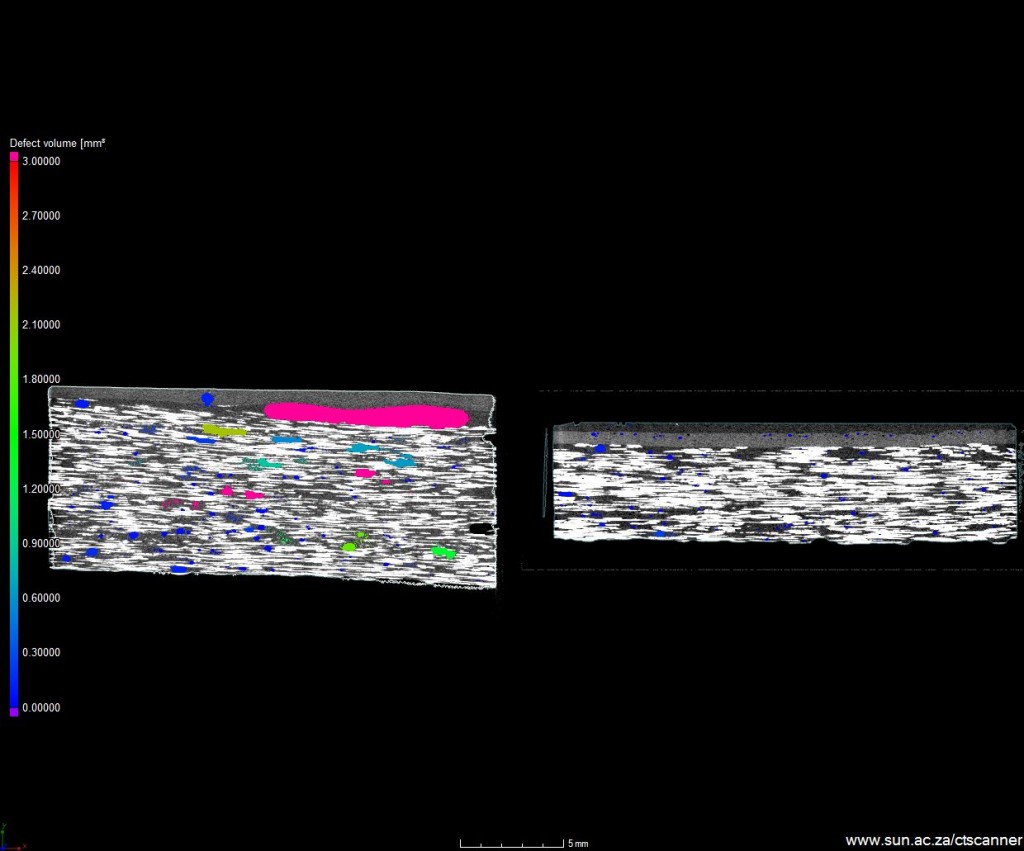

No we cannot CT scan your whole swimming pool, not non-destructively anyway. What we can do is take a sample of fibreglass from where the weir is cut out, and analyze that section. In this example, two samples of different fibreglass pool manufacturing methods are compared. These are the chopper gun application (sample 1) and the hand lamination method (sample 2). We do not endorse one or the other and have done a comparison based on one sample of each, but the newly installed pool shown is of the chopper gun application type. The chopper gun sample has a lower average porosity while the hand lamination method has a higher average porosity as well as larger pores in general. In this project, large sections were scanned followed by a high resolution scan of small sections to see more details.

VIDEOS:

ROTATION OF POROSITY COMPARISON: Rotation

SLICE VIDEO: SLICE MOVIE POOL

Follow

Follow

2 pings