This example shows a typical microCT analysis of 3D printed parts. 3D printing and additive manufacturing technologies differ widely and quality control of these parts are very important. In this example, Markforged parts were scanned of the following types: 1. Nylon 2. Short fibres in onyx plastic 3. Long fibres in nylon Here is a …

Category: Plastics

May 19

Metrology of a 3D printed logo

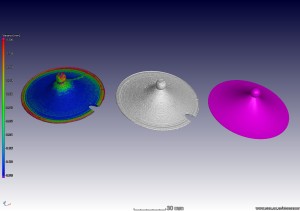

A 3D printed Stellenbosch University logo was designed and manufactured at the Stellenbosch Idea2Product lab, a division of the CT Scanner Facility which is located at the university’s Launchlab: http://blogs.sun.ac.za/idea2product This logo which is roughly 30 x 30 x 14 mm is intended to be used for marketing purposes, but also provides a nice …

Feb 12

3D Printed Sugar Pot Test

As an example a Sugar Bowl and Spoon was 3D printed for the CT Scanner Facility (Figure 1) all clients are welcome to come and make use of this with their free coffee. This was a great opportunity to show how these techniques (3D Scanning and Printing) can be used in conjunction. The sugar pot …

Dec 04

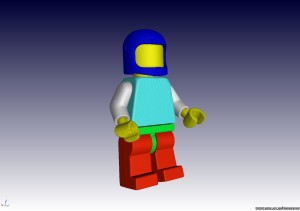

LEGO Man Segmentation

Over the past year we have made significant advances in our analysis capabilities on CT data. The main addition to our skillsets is the ability to perform more advanced segmentation on samples with small differences in density. In the case of most CT data sets this is the most difficult part, since in general parts …

Sep 25

Swimming pool analysis

No we cannot CT scan your whole swimming pool, not non-destructively anyway. What we can do is take a sample of fibreglass from where the weir is cut out, and analyze that section. In this example, two samples of different fibreglass pool manufacturing methods are compared. These are the chopper gun application (sample 1) and …

Sep 25

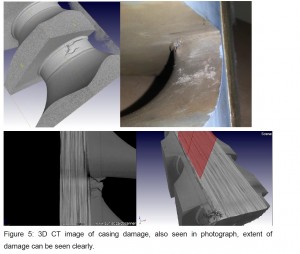

Damaged High Voltage Insulator

In this proof of concept, a damaged HV insulator used in power line transmission was scanned to see if internal damage can be assessed positively. The idea is to scan these objects preventatively before serious failure. Some images show the damage subsurface and the clarity of routine-type 3D X-ray inspection.

Follow

Follow