In this work, a Titanium aerospace investment casting was analyzed by X-ray micro Computed Tomography (X-ray microCT). The geometry cast and evaluated was supplied by Boeing, and was supplied to CSIR as a design file. This geometry is used to benchmark titanium casting processes and suppliers against aerospace standards. Key features of interest are internal pockets, lugs, and varying thicknesses. Typical evaluations are dimensional, internal soundness, surface finish, and mechanical properties. The sample was supplied to the Stellenbosch University CT Scanner Facility for analysis. Traditional non-destructive test methods such as radiographic testing and ultrasound can be used to detect internal defects successfully, but X-ray microCT allows a more detailed view of the these defects as demonstrated in this technical note.

Figure 1: Digital X-ray image of Titanium investment casting

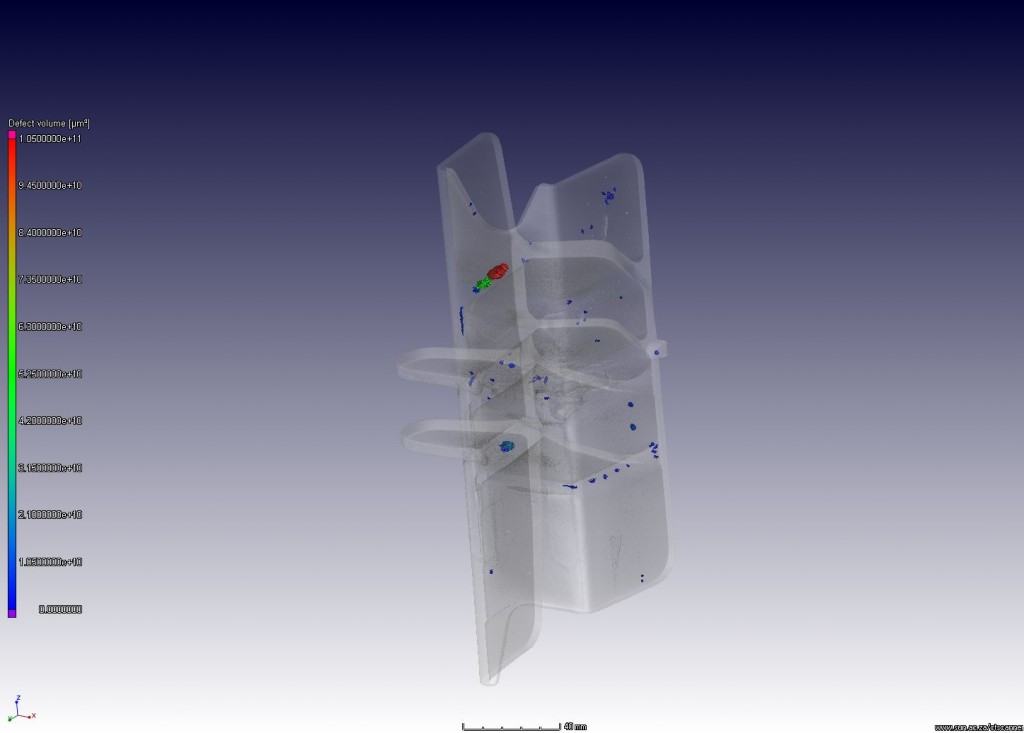

Figure 2: Defect analysis indicating the location, shape and size of each defect larger than 1 mm.

MOVIE:

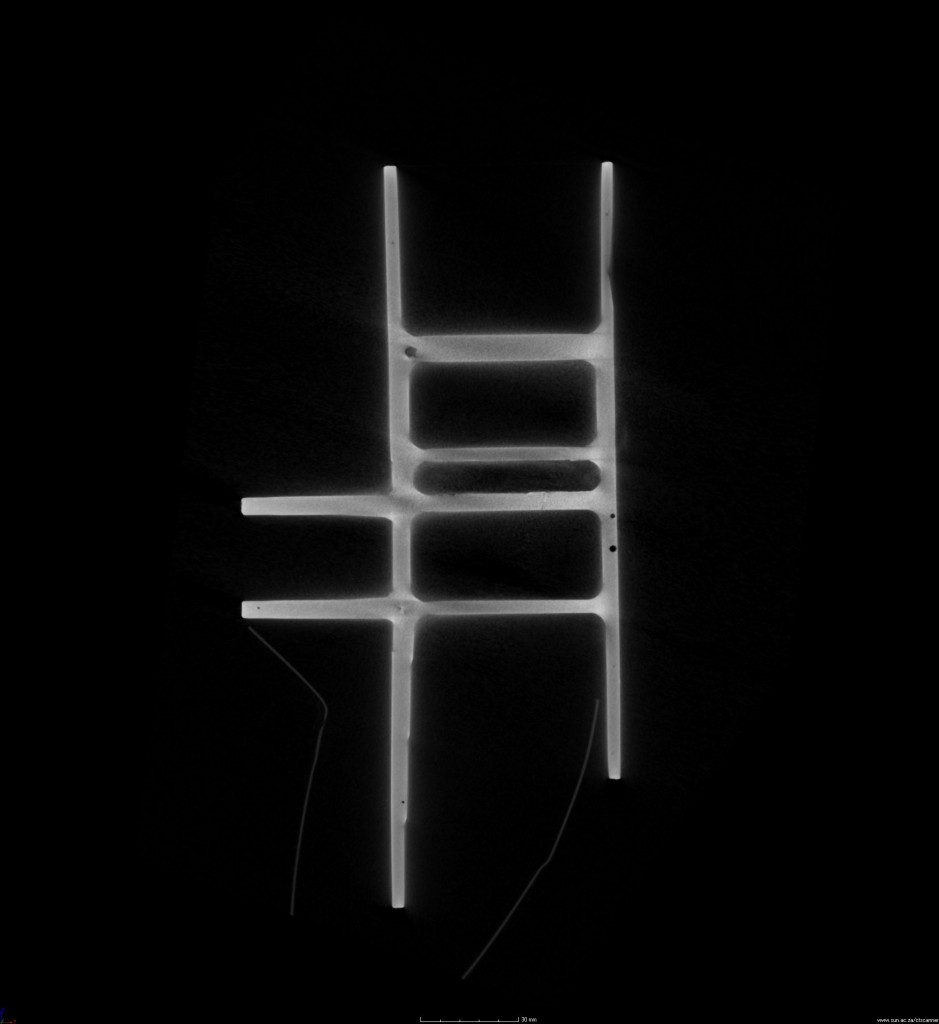

Figure 3: CT Slice image of the casting

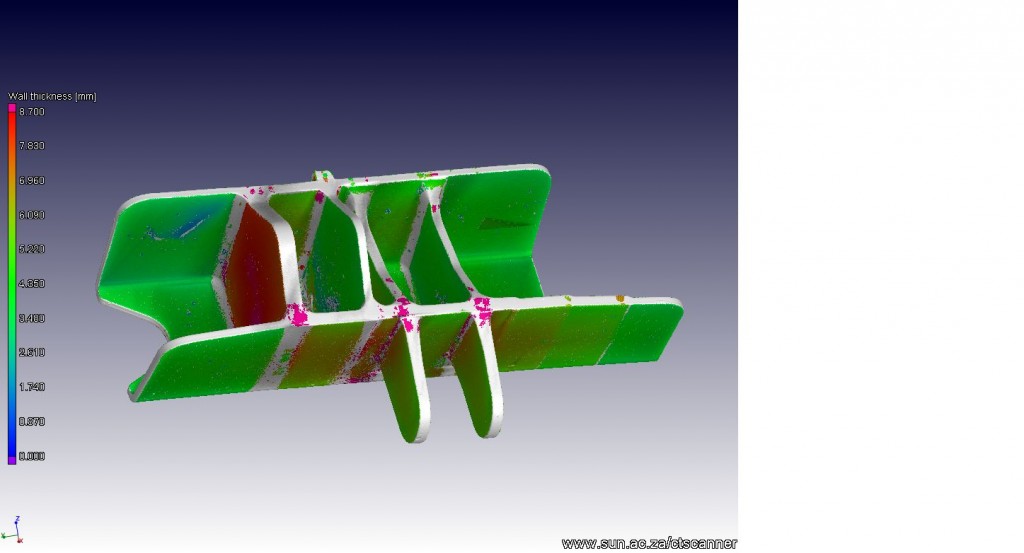

Figure 4: Wall thickness analysis of casting

MOVIE:

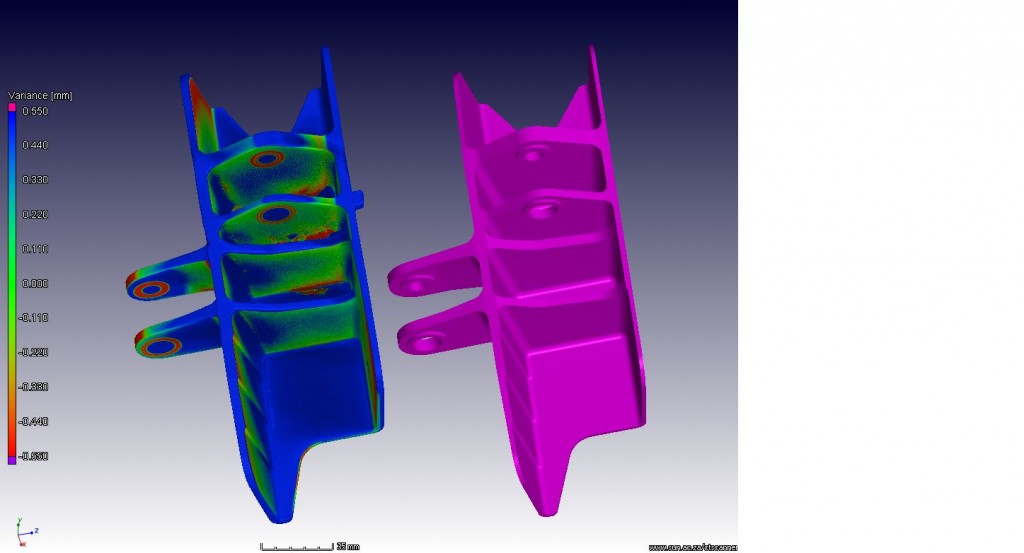

Figure 5: Part to CAD comparison of the casting

MOVIE:

It has been demonstrated that very useful information can be obtained from automatic analysis of X-ray microCT scans of a casting. Defect analysis, wall thickness analysis and part to CAD comparisons were demonstrated. It would be of particular interest to industrial companies that the nondestructive analysis reported here was performed in less than 4 hours. For lower quality and hence less stringent testing requirements, smaller components or large batches of samples, this time and hence cost can even be significantly reduced further.

THIS WORK WAS CARRIED OUT FOR THE CSIR AND WAS APPROVED FOR PUBLIC RELEASE BY BOEING

FURTHER DETAILS ARE AVAILABLE ON REQUEST

Analysis performed in Volume Graphics VGStudioMax 2.2

Follow

Follow

2 pings