Author's posts

Jan 12

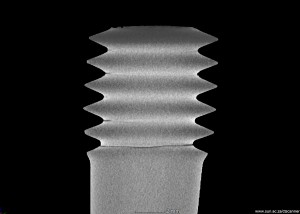

First print from CT data

Our first 3D print from a nanoCT scan data set (blown up from 1 mm to 150 mm length) was successful! In this image the happy client is holding his 3D print of a microstructure within his material. This is a great way to visualize and demonstrate 3D information, great for presentations. When added to …

Jan 10

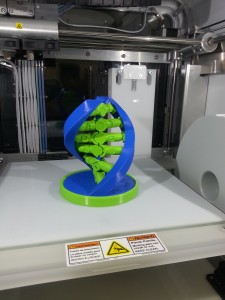

First 3d print

Our first 3D print is completed! As experts in 3D scanning, taking visualization to the next level with physical prints is something we’ve been looking forward to for a long time. This first print is a DNA helix – not a CT Scan data set just yet. 3D printing will be offered as an accessible …

Nov 19

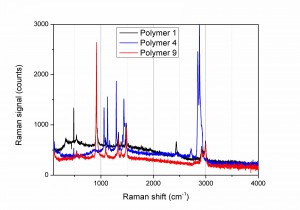

We’ve got Raman!

Raman spectroscopy is a powerful technique which allows materials to be discriminated from each other based on their Raman spectral fingerprints. It is used for qualitative testing of material types, eg. testing if milk powder contains melamine, or can be used for quantitative investigations by setting up calibration models. We have available a newly installed …

Oct 30

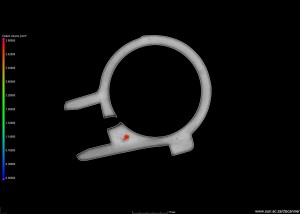

Investigating microwave induced cracks

Edson Charikinya won the best young author award at the International Mineral Processing Congress in Chile, for his paper: “Use of X-ray computed tomography to investigate microwave induced cracks in sphalerite ore particles”. Edson is a final year PhD student from Stellenbosch University Chemical Engineering. His award winning presentation and a corresponding poster from another …

Oct 30

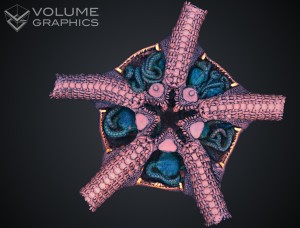

Biology – looking inside brittlestars

This work is from Jannes Landschoff, who won the best poster award for his poster “How many inside? A 3D Micro CT-Scan of Brooding Ophiuroids” at the European Echinoderms Colloquium, Portsmouth, UK in July. Jannes is a MSc student from UCT Biology. This work is still ongoing so more striking images will be loaded once …

Follow

Follow